WAVY TRAY

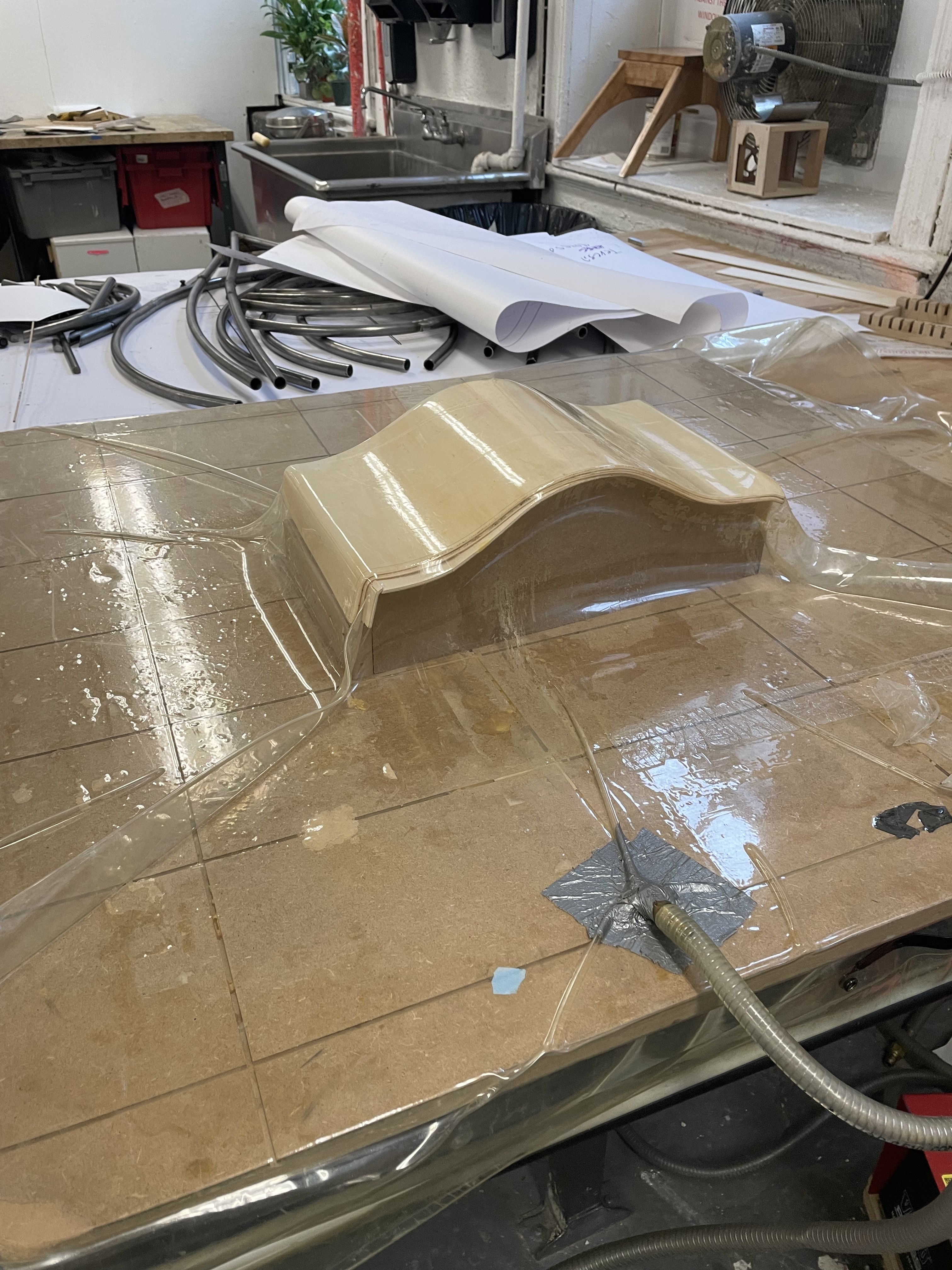

For this project, we were introduced to the different ways of manipulating wood. We were tasked to create a complex mold that would allow us to mass-produce several versions of the same form.

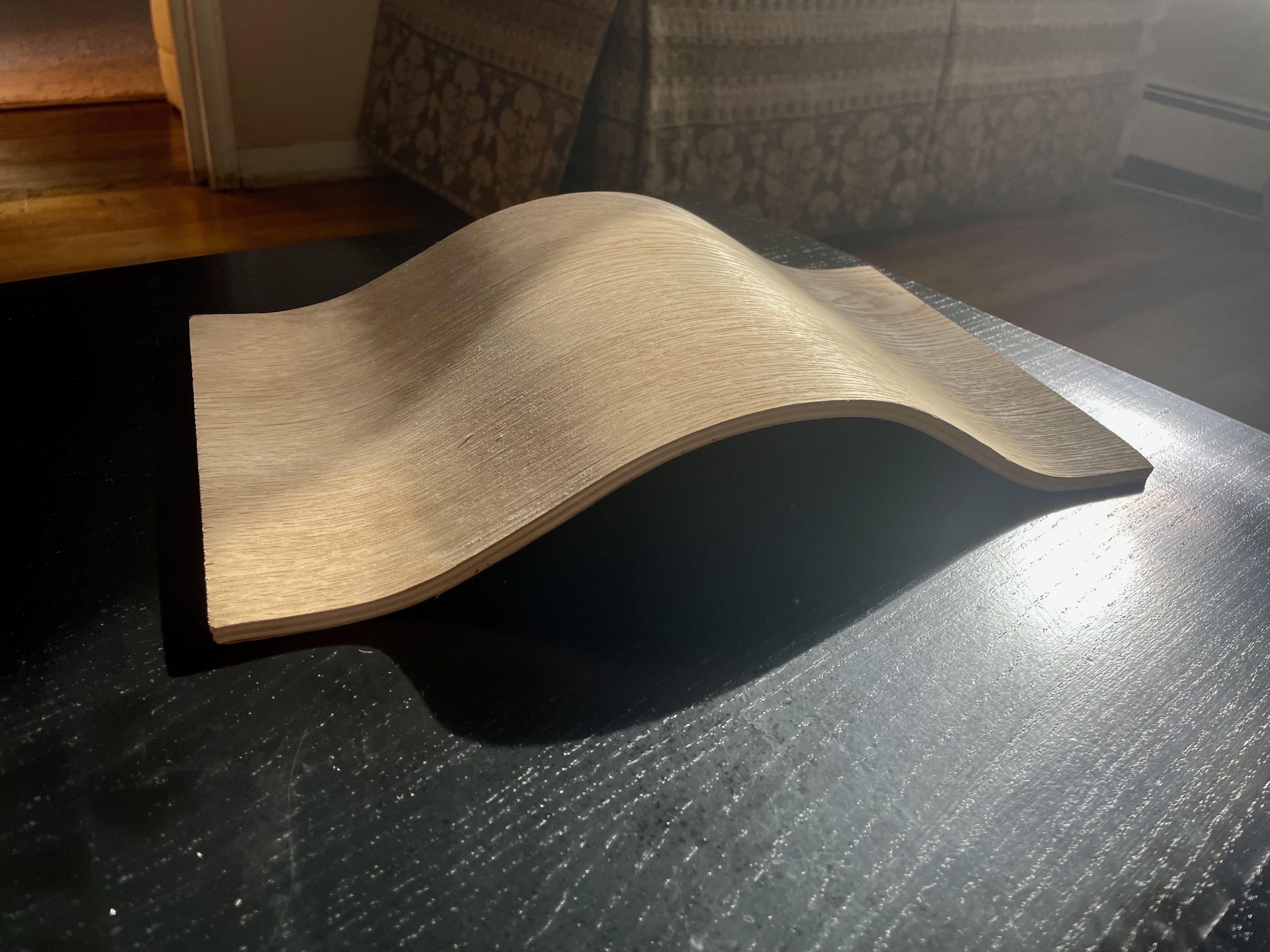

- sleek red-oak wood finish

- decorative conversation piece

- impractical organic forms

- could be styled flipside or vertically

- small enough to liven any empty space

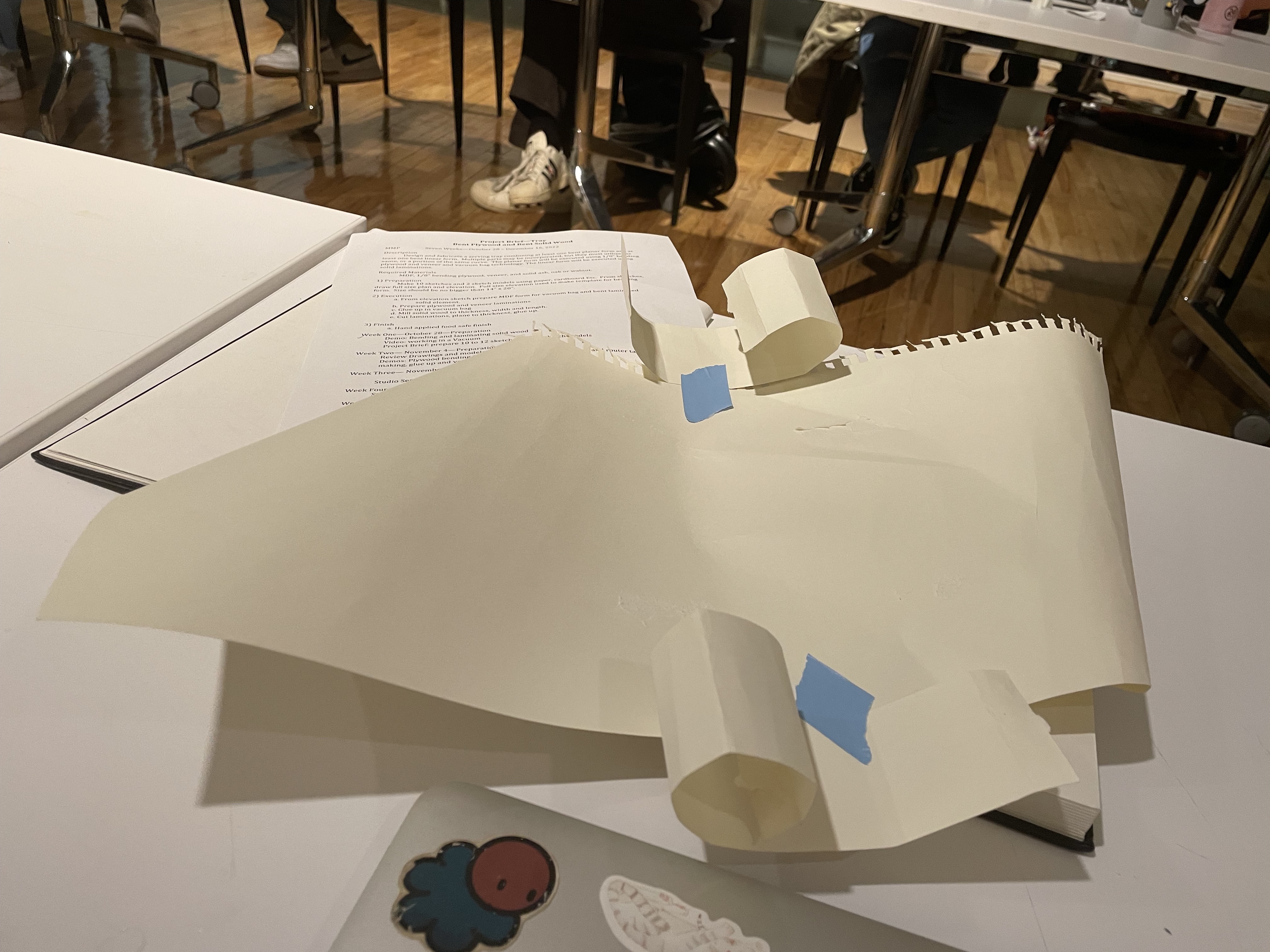

SKETCH MODEL

MATERIAL RESEARCH

.25″ PLYWOOD

![]()

MDF

![]()

RED-OAK VENEER

![]()

PROCESS

FINAL PROTOTYPE

The Wavy Tray has a bridge-like curvature that allows it to rock back and forth. It’s playful and impractical, but it’s character makes it a great subtle centerpiece to any spot in your home. Whether you prefer it right side up or flipside, the possibilities of balancing something on the tray aren’t endless! But the unconventional and sleek finish of the elegant wooden forms adds just the right touch to any space.

TO LUNAR LUMINAIRE︎